HERMS Ramping Experiments

While I was doing a 15 gallon turbid mash with 5 temperature steps, I

decided to do some research into performance of different

temperature control algorithms.

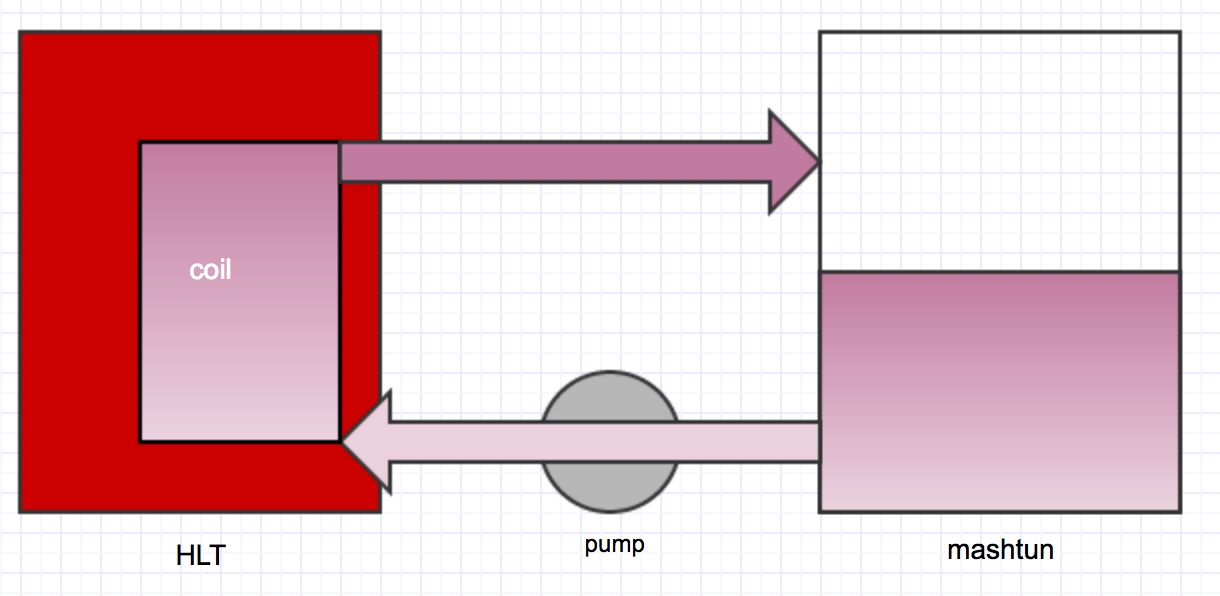

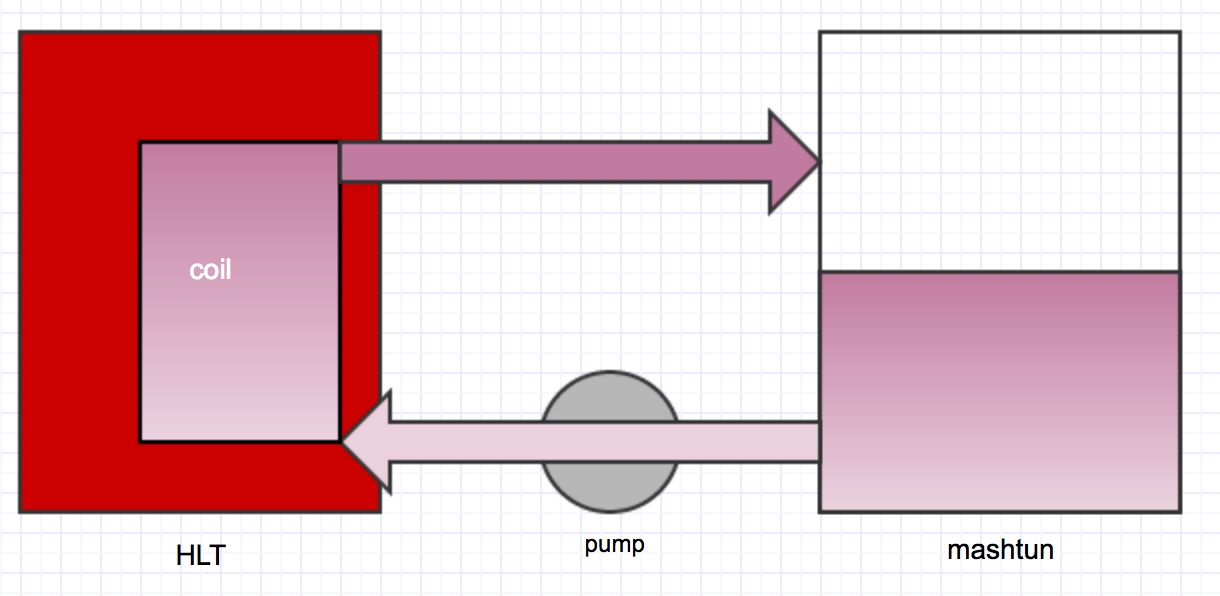

Common practise on a HERMS system is to control the mash

temperature indirectly by varying the temperature of a

direct-fired hot liquor tank. Wort flows out of the mashtun,

via a pump, and through a heat-exchanger coil in the hot liquor

tank and then returns to the mashtun. If you want your mash to

be 65℃, then setting your HLT to 65℃ is a reasonable

approach. In a world with no thermal losses, this model should work

well.

In reality, thermal losses from the HLT, hoses, and pumps leads

to a condition where there is a small differential between the

HLT and mashtun. My home brewhouse, which consists of an 80 litre

(20 gallon)

mashtun, a 60 litre (15 gallon) HLT fired by a 5500W electric element, and a 14m (45 foot) HERMS coil driven by a

pump that moves 10 litres of wort per minute through the coil

typically requires the HLT to be set around 1 - 1.5℃ hotter

than the mashtun when brewing 60L batches. This can vary

slightly based on the temperature setpoint, mass of grain,

volume of water in the mashtun, and volume of water in the HLT.

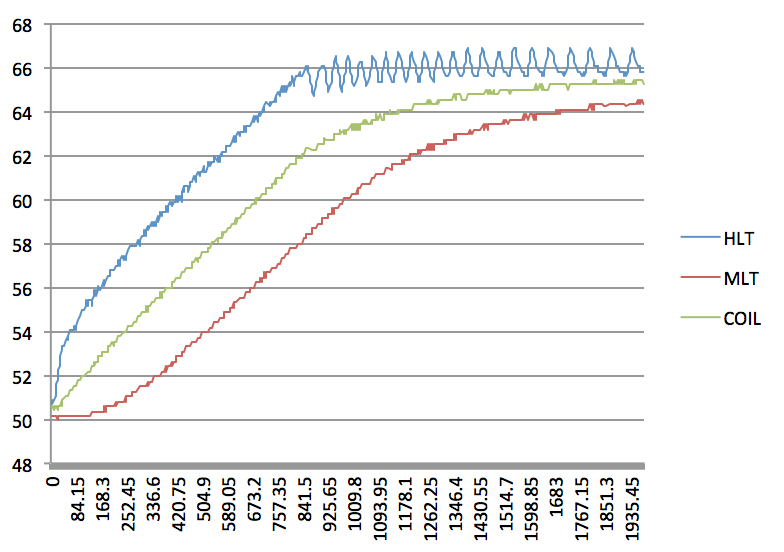

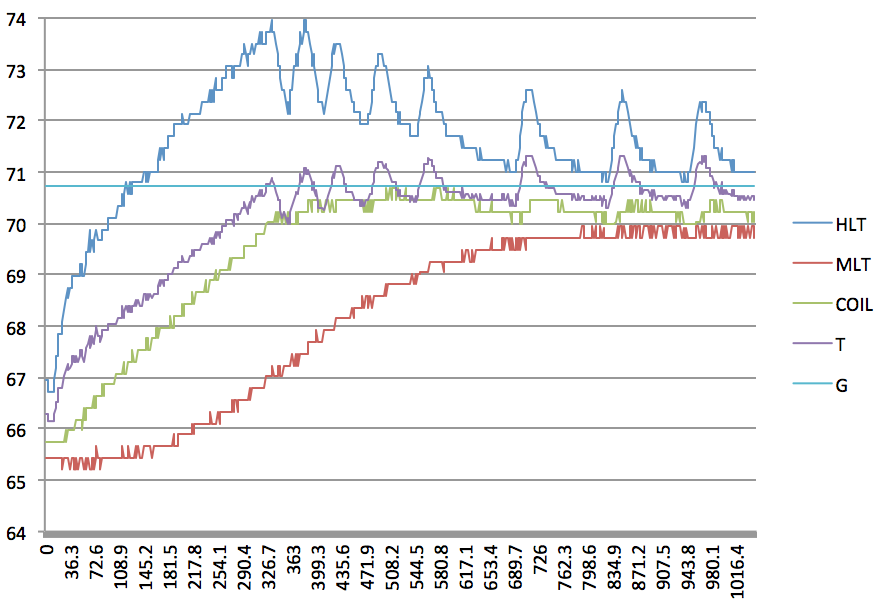

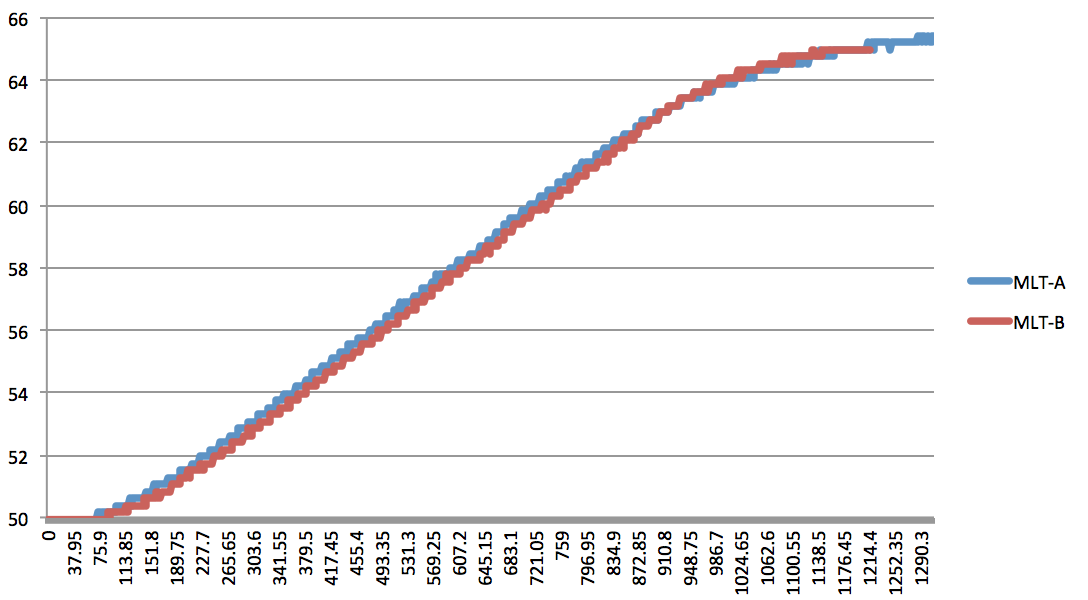

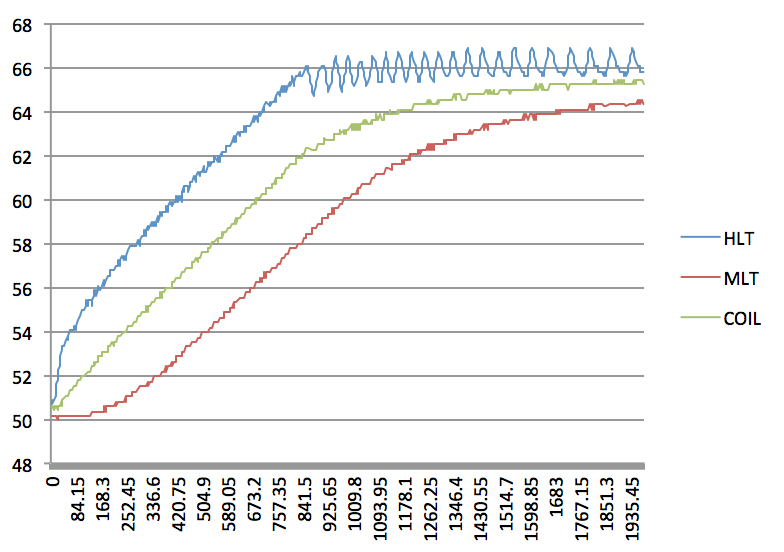

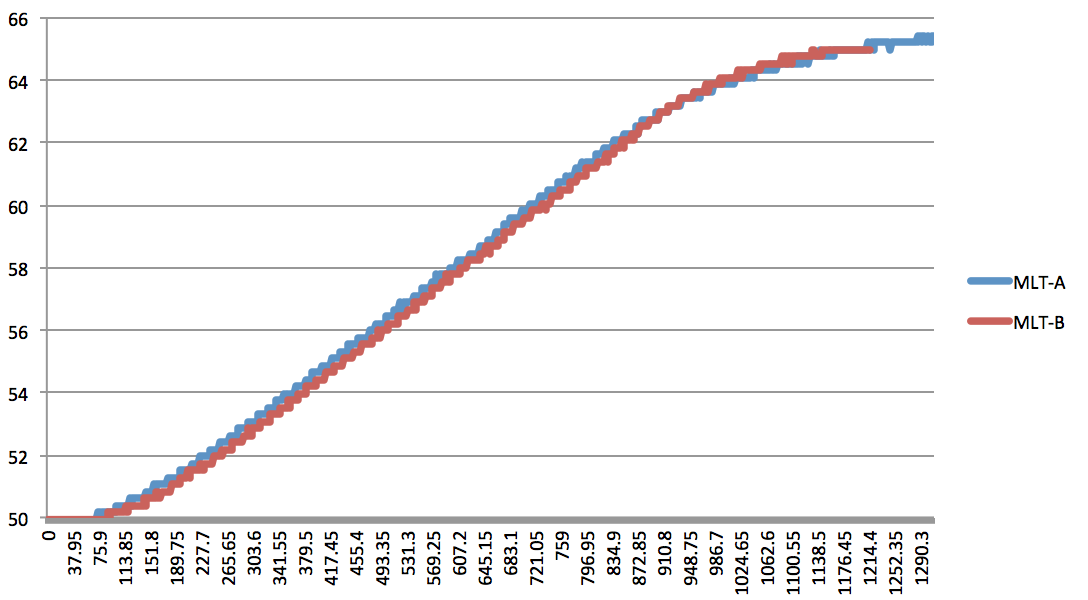

Here is a plot of my system's response when ramping the mashtun

from 50℃ to 65℃.

The blue curve represents the temperature in the HLT. The green

curve represents the temeprature of the wort at the exit point

from the heat exchanger coil where it returns to the top of the mashtun.

The red curve represents the temperature of the wort at the

bottom of the mashtun as it exits the vessel and heads towards

the pump. The thermal gradient in the HLT is minimized by a

recirculating pump which keeps the tank stirred and fairly

uniform. You can see here that my HLT setpoint is just over

66℃. There is a control deadband of about 0.5℃ around

the setpoint, which is why a zig-zag response can be seen.

Rate of Heat Transfer

If an equal mass of hot and cold water are mixed together, the

resulting final temperature of the combined system is a weighted

mid-point between the two initial temperatures. e.g., 10L at

20℃ and 10L at 30℃ yields 20L at 25℃. In a

heat-exchanger like a HERMS coil, the volumes don't actually mix,

but instead flow past each other at a specific rate for a specific

period of time. This results in a slight cooling of the water in

the HLT and a warming of the wort flowing through

the coil. The rate at which heat transfers across the stainless

steel wall of the heat exchanger coil is determined by

its thermal

conductivity and the difference in temperature on the inside

and outide. In a nutshell, the larger the difference in

temperature on either side of the wall, the quicker the transfer of

energy (heat). This is the same reason an ice cube melts faster in

hot water than in cool water. A final point to note here is that

the temperature of the wort leaving the heat exchanger will never

fully reach the same temperature as the water in the HLT, since the

system is trying to reach a point in between the temperature on the

inside and outside of the coil. The wort can get closer and closer

to the HLT temperature the longer it stays in the coil, but it will

only asymptotically approach the HLT temperature. You can see this

in the above graph -- when the HLT and wort temperatures are

further apart, the rate at which heat is transferred is faster

(steeper slope), but when the temperatures are closer together (at

the start and end of the ramp), the rate of change is slower

Purposely Overshooting

By allowing the temperature of the HLT to overshoot the target

mash temperature by a calculated amount, it is possible to

reduce the time required for the mash to reach it's final

temperature. This is because the temperature differential in the

heat exchanger is being increased, thus increasing the rate of

heat transfer.

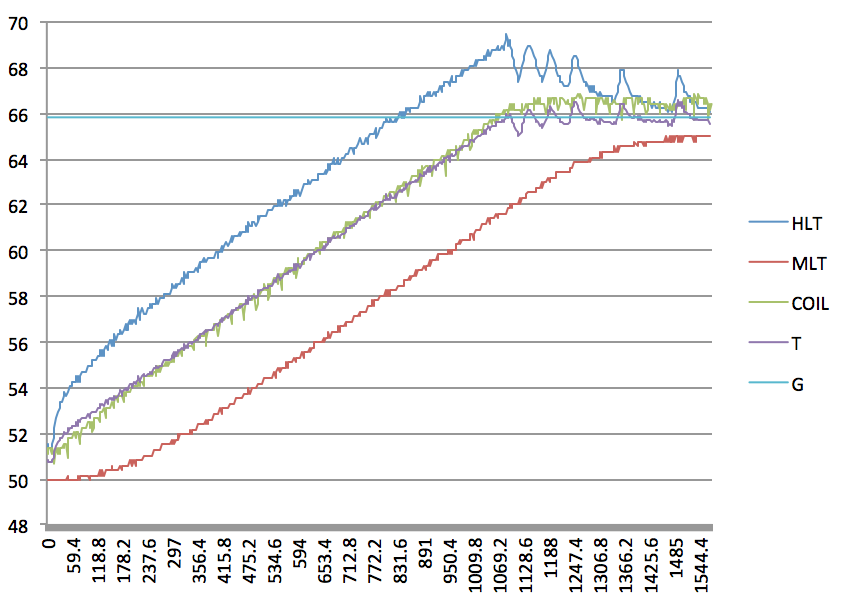

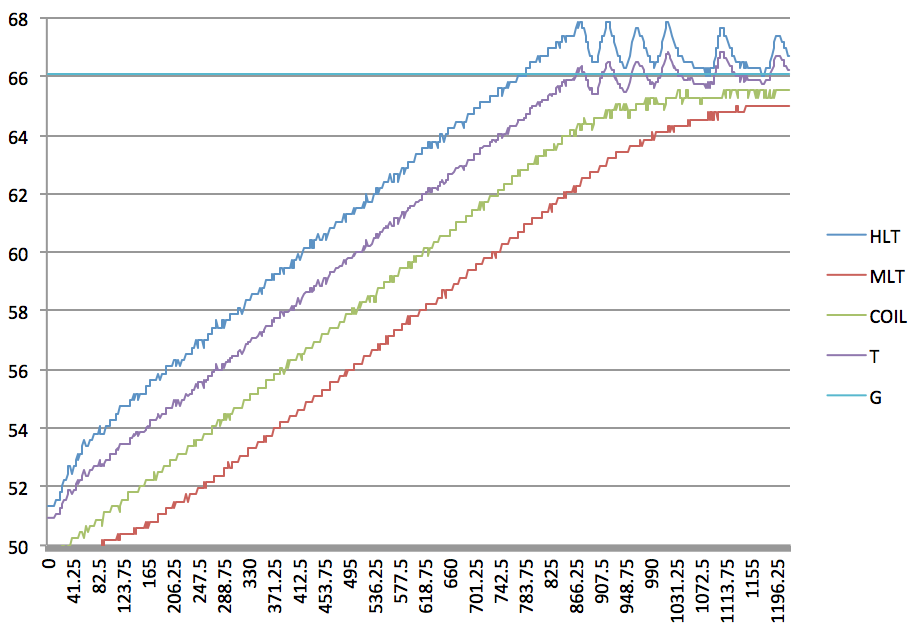

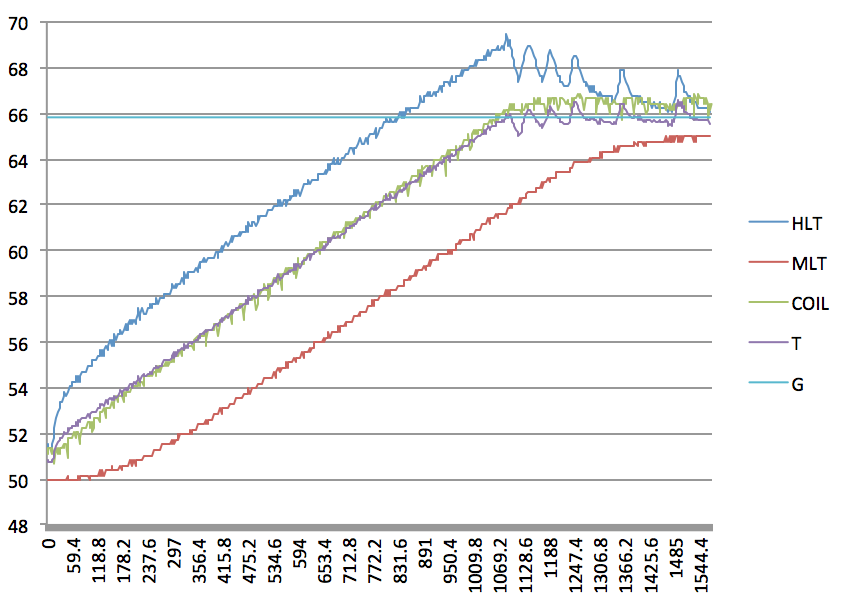

You'll note that 2 new curves are plotted here -- T and G. The T

curve indicates the overall system temperature, which is the

weighted sum of the thermal masses of both the HLT water and the

mash. G is the final weighted goal state for T.

The formula I am using to compute the current system temperature

(T) is:

T = kHLT × tHLT + kMLT ×

tMLT

where:

- kHLT is the proportion of mass in the HLT (e.g., 50 /

(40+50) = 0.556)

- kMLT is the proportion of mass in the mashtun (e.g., 40 /

(40+50) = 0.444)

- tHLT is the temperature of the water in

the HLT

- tMLT is the temperature of the mash in

the mashtun

And the goal (G) is defined as my desired final steady-state

arrangement where tMLT = 65℃, and

tHLT = 65℃ + tOFFSET,

with tOFFSET being the known offset that I need

to maintain my HLT at in order to hold a given mash temeprature

(approximately 1.5℃ in this case). This yields a goal

state of:

G = 0.556 * (65 + 1.5) + 0.444 * 65 =

65.834℃

When the system temperature reaches this point, I know that there is an equivalent

amount of heat in the system to reach my goal condition where

the mash temperature is at my desired setpoint and the HLT is

a bit warmer to maintain that mash temperature. The heat may

not yet be evenly distributed, but in a closed system with no

losses, the heat exchanger would take care of that. This is the

important bit...

The two vessels are considered to be a single

system, and energy is only added to the system when the overall

temperature is below the goal.

You can see that the HLT reaches 66℃ at about the same time

as in the previous case, but instead of cutting the power

at that point, the HLT is allowed to continue heating up until

the overall system temperature (T) reaches the goal (G). Again, the

reasoning here is that the heat-exchanger will finish the work of

moving the excess energy from the HLT to the mash. As a result of this HLT overshoot,

the temperature difference between HLT and mash is allowed to

remain larger for a longer period of time, thereby increasing the

rate at which energy is transferred to the wort. Additionally, without

any further energy input, the overall system temperature (T)

cannot increase any further, which ensures the mash doesn't

overshoot. When the 2

graphs are co-plotted, you can see that there is a time savings

of around 25%, or over 8.5 minutes:

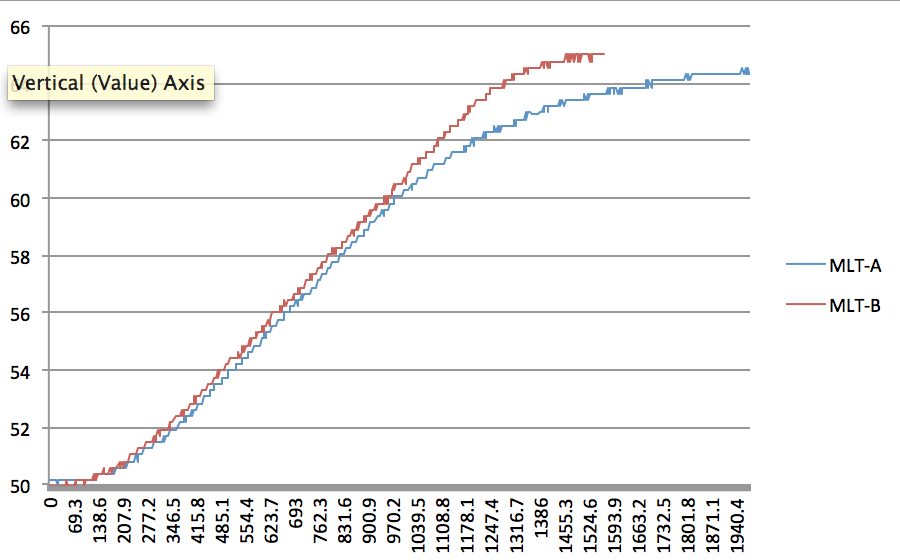

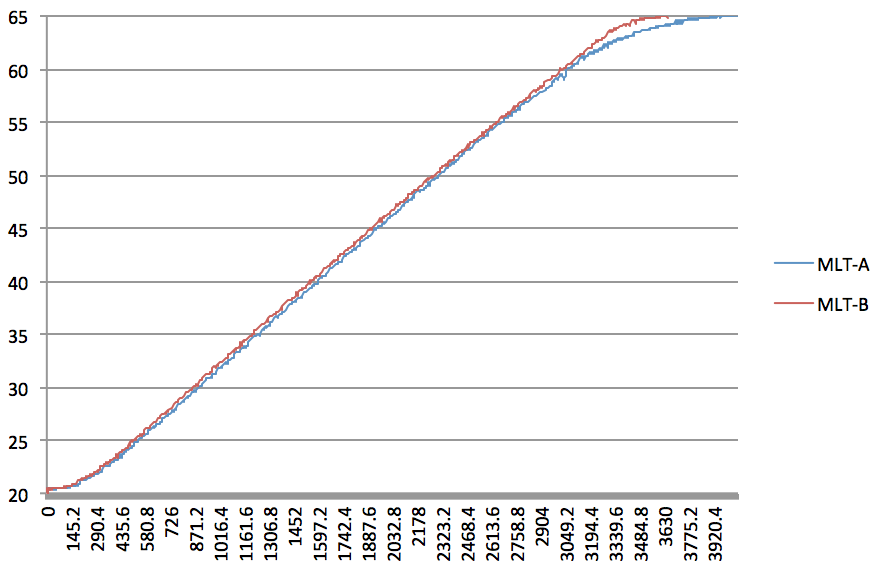

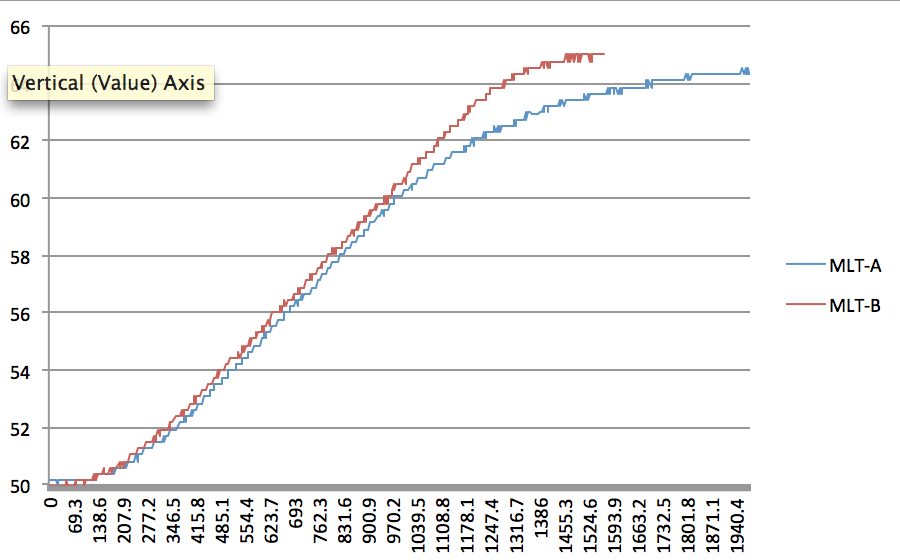

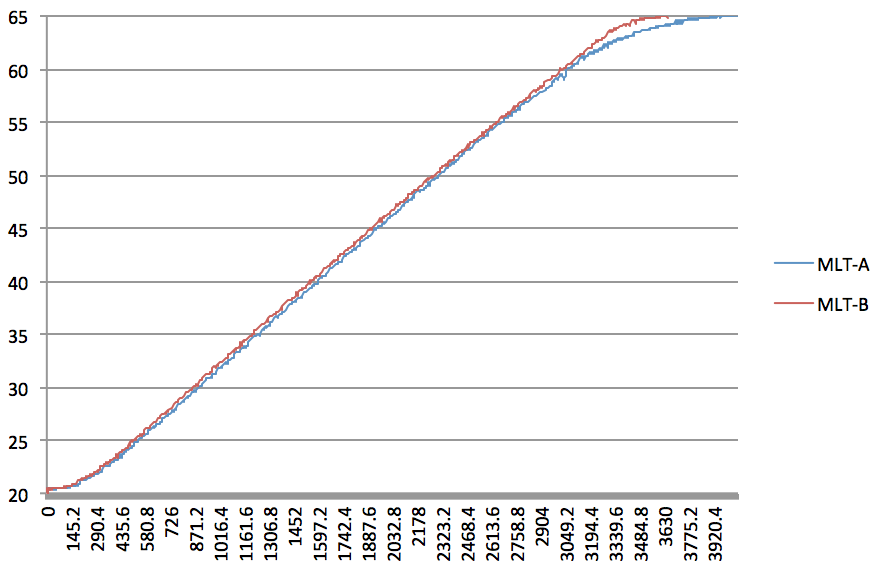

You can see the simple control algorithm's impact on the

mashtun temperature as the blue MLT-A curve, and the overshoot

algorithm's impact as the red MLT-B curve.

As a note, my turbid mash schedule required a dough-in at 45℃ and

rests at 50℃, 65℃, 70℃, and a mash-out to

76℃. In the end, for this 15 gallon batch, I saved almost 30 minutes by using this

overshooting control algorithm.

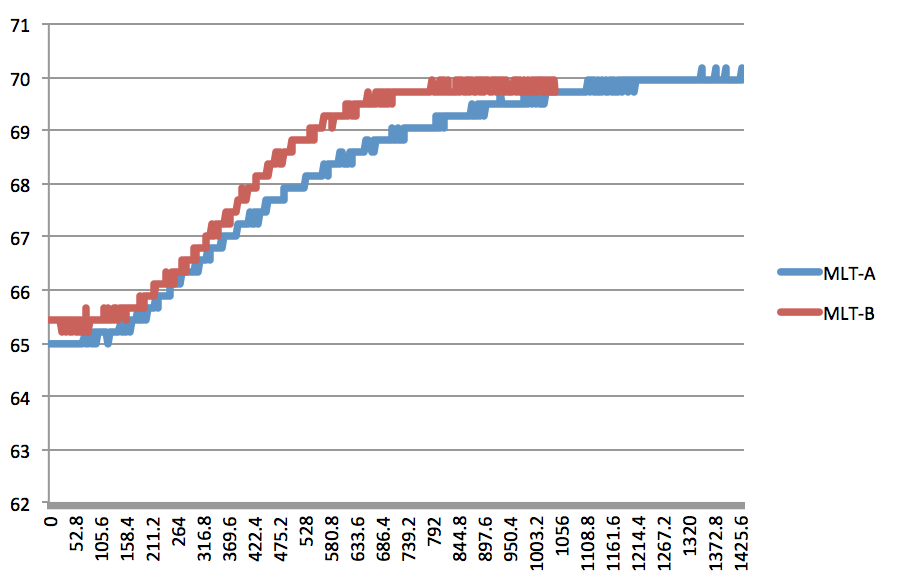

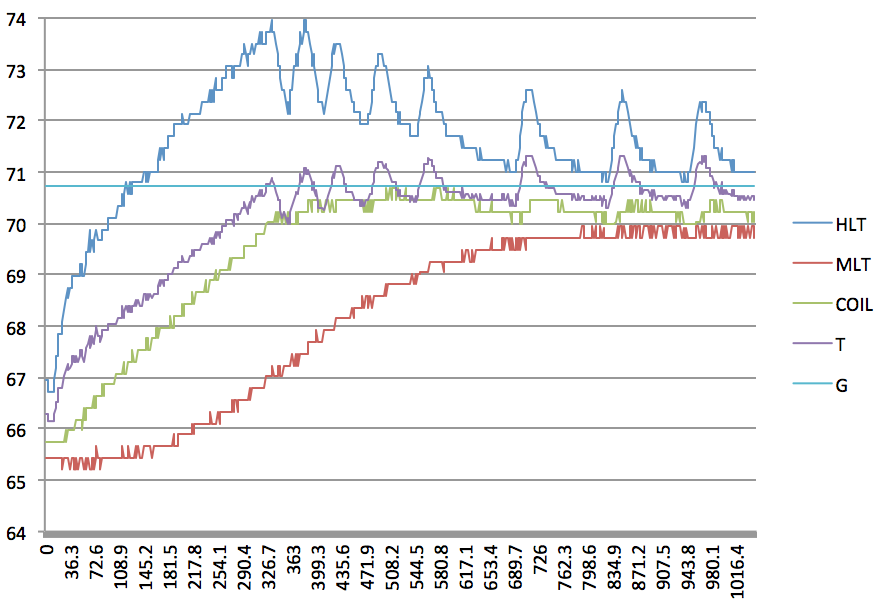

Overheating the Mash?

Is it possible that the over-heated HLT could lead to

de-naturing of the enzymes in the wort? If you are ramping

temperature for dough-in or mash-out, this shouldn't be a

concern, however if you are doing temperature ramps for alpha-

or beta-amylase rests, then it might be. Let's take a quick

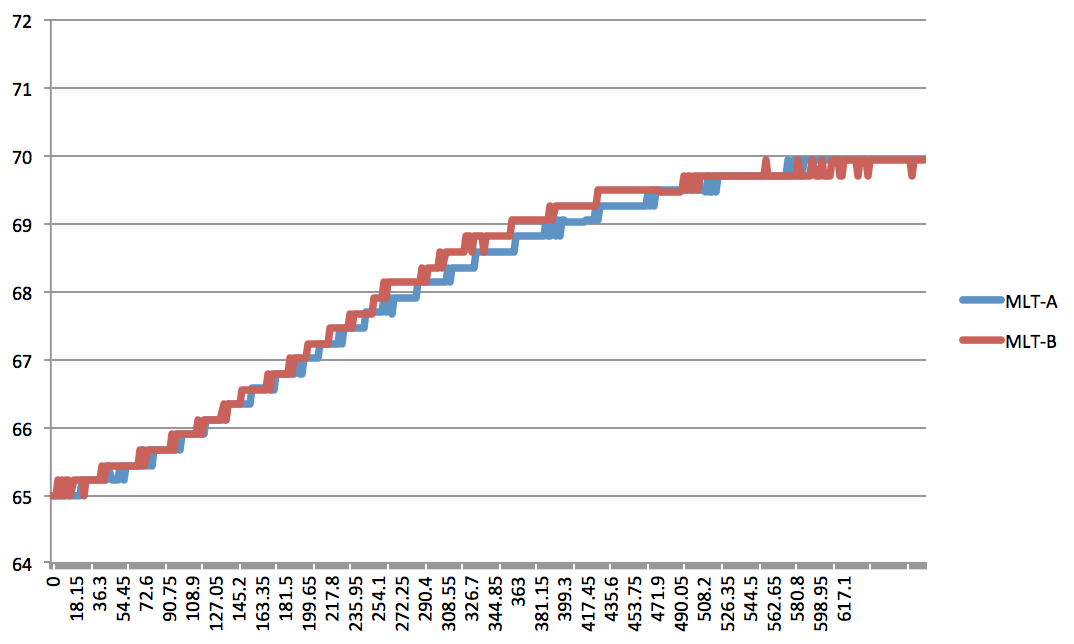

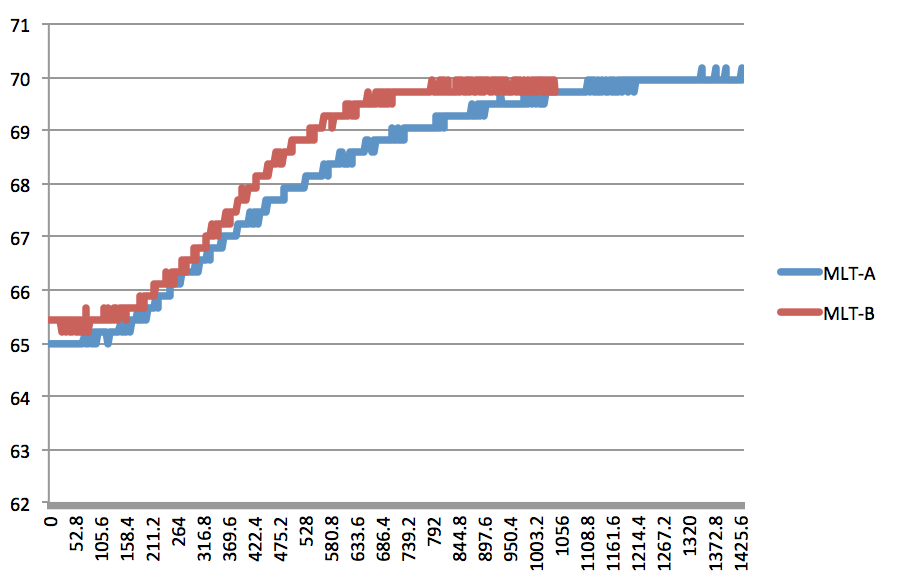

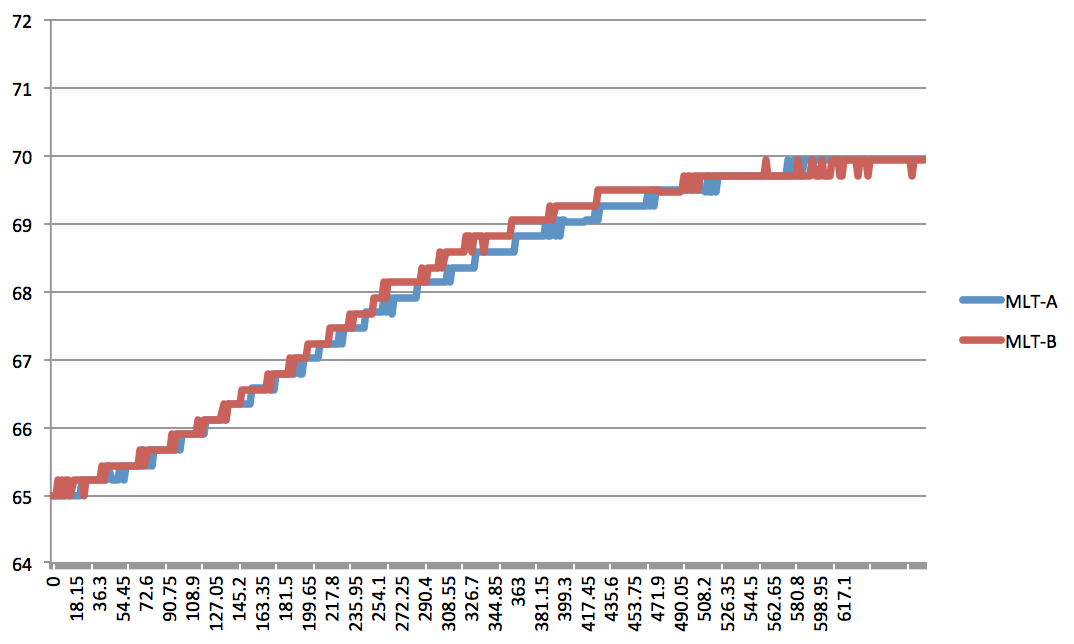

look at a section of one of my temperature plots for a 65℃

- 70℃ ramp.

You can see that the green curve does exceed the mash setpoint

of 70℃, but

recall that the green curve in my system is always slightly

higher than the mash temperature, due to the nature of the

losses in the system. The difference in temperature from my

setpoint appears to only be around 0.5 - 0.7℃ in this

case. While that may be enough to impart an accelerated

denaturing, keep in mind that the wort will only reach this peak

temperature just as it is finishing it's run through the HERMS

coil. If the wort is only overheated for a brief moment before

rejoining the full volume of the mashtun and equalizing, then

the denaturing effect is greatly reduced.

- My pump moves 10 litres per minute through the coil.

- The volume of my HERM coil is approximately 1.75

litres.

- 1.75 litres will be moved through the coil in 10

seconds.

- The temperature gradient through the coil is at most around 4℃

in the above plot (inflow to outflow).

- This means that only around 15-20% of the wort in the coil

will be above 70℃ at any given time.

- 20% of 10 seconds is 2 seconds, so the wort is only

overheated slightly for 2 seconds.

- It takes 240 seconds to completely cycle the 40 litres of

wort through the HERMS coil.

- The wort only spends 0.8% of it's time above the 70℃ setpoint.

Now I don't know specifically how long it takes to denature the

enzymes, but if the wort is only overheated at a duty cycle of

less than 1% (14 seconds over a 30 minute step) and only by an amount on the order of half a

degree, then I am not overly concerned. Also, keep in mind that

this overshoot only exists for a small duration of time during

the temperature ramp, after which point, steady state is

resumed (although I always have a slightly higher HLT setpoint

than my mash). Frankly, I would have

more concern if I were operating a RIMS system which applies a

much greater localized heat differential to the wort, or moreso

during a typical single-infusion mash where the full quantity of grist is purposely immersed in

over-heated strike water.

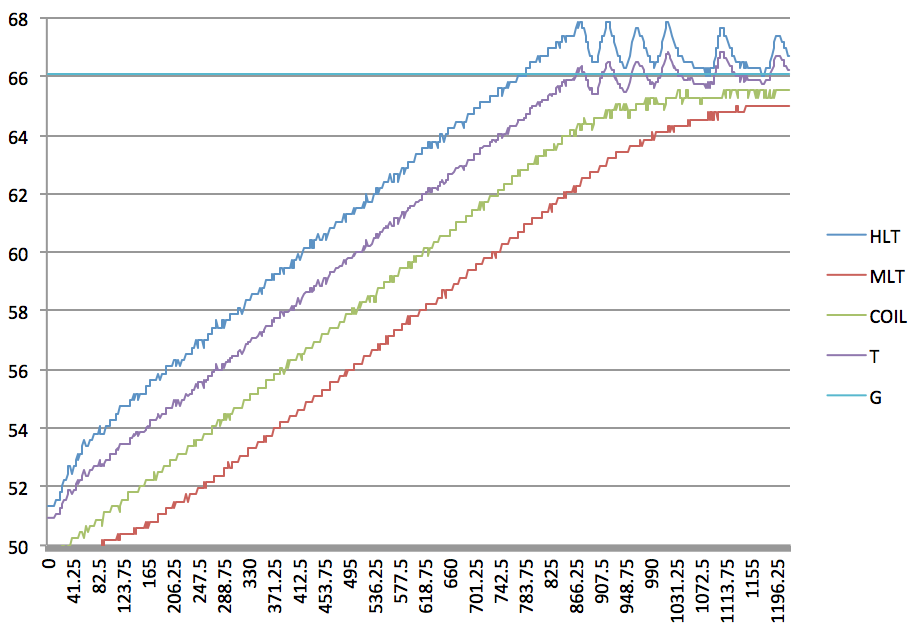

Comparisons at 40kg

Here are a series of comparative plots for my 40kg setup ramping

between different temperature points and a note on how much time

was saved using the overshoot algorithm. The 40kg figure comes

from the specific grain bill I was using for my last brew which

was approximately 34kg of water plus 13kg of grain (34 + 0.45 ×

13 = 39.85kg equivalent thermal mass). My HLT was filled with

50kg of water.

Ramp from 20℃ to 65℃ (strike). 362 seconds saved

(10%). Probably the most underwhelming, percentage-wise, but in

absolute terms, that's still 6 minutes.

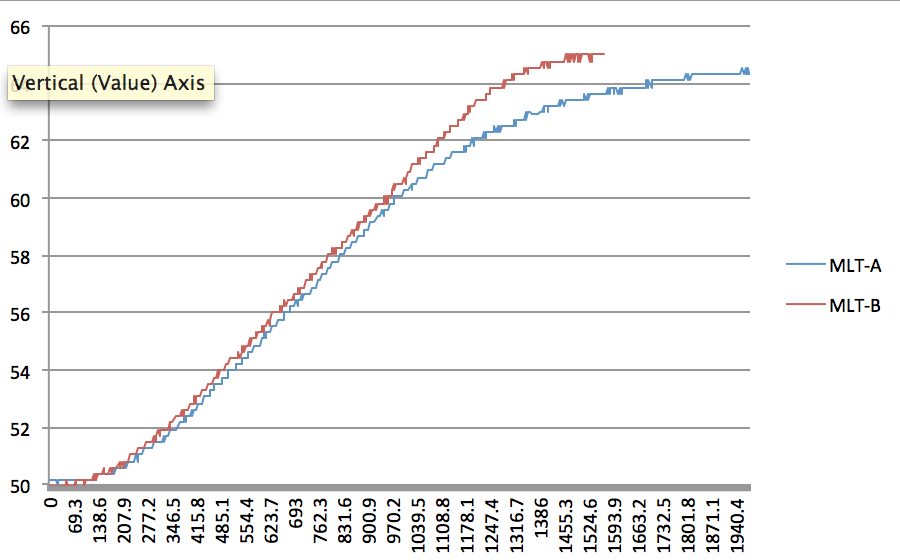

Ramp from 50℃ to 65℃ (protein to beta). 517 seconds

saved (26%).

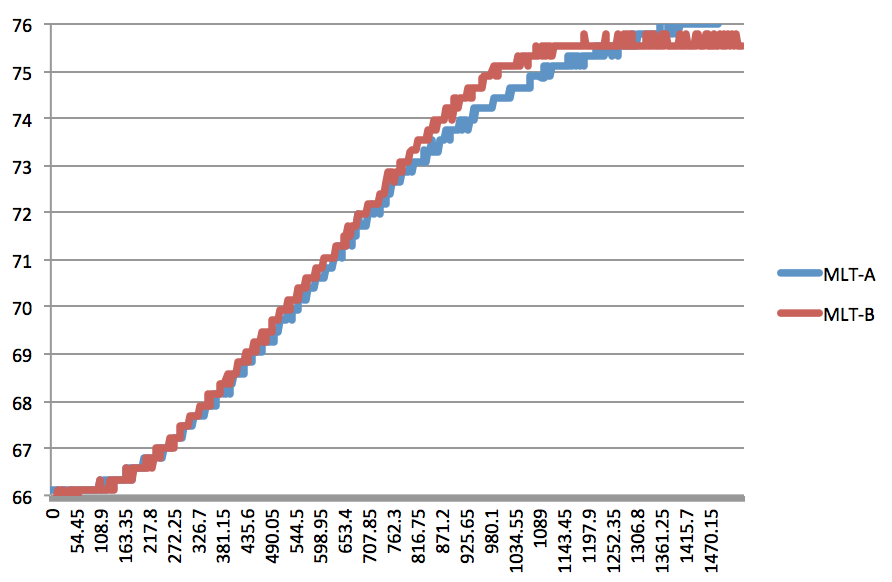

Ramp from 65℃ to 70℃ (beta to alpha). 330 seconds saved

(30%). Over 5 minutes in a 5 degree ramp.

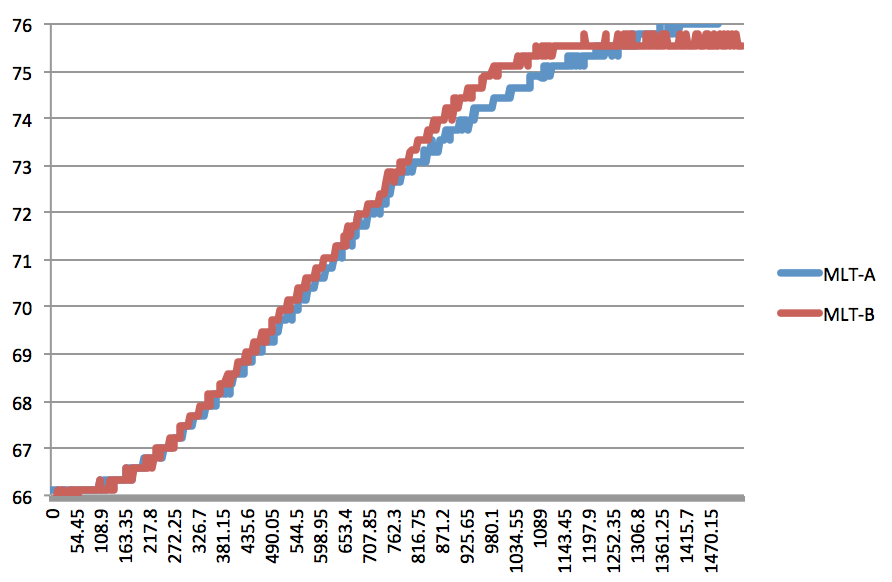

Ramp from 66℃ to 76℃ (mash-out). 170 seconds saved

(13%). For mash-out, we can typically do better, since the final

temperature isn't really that important. If you are going to keep

heating your HLT for lautering (e.g., 90℃), then you can save

even more time here by just letting it keep firing, pulling the

mash up faster.

Variables

After some discussion with members of my local club, some

concerns were raised that the performance of my system is

different from that of others. Specifically, the temperature of

my mashtun was lagging by several degrees when ramping, wheras

others reported only 1-2 degrees. It's true. Different behaviours

will be seen when system variables are adjusted:

- Decreasing the mass in the mashtun reduces the thermal lag

during ramp since the volume cycles quicker through the heat exchanger,

and the ratio of returning wort at warmer temperature to

cooler wort in the mashtun is larger.

- Increasing the mass in the HLT reduces the thermal lag

during ramp since the HLT has more thermal mass and does not

cool off as quickly overall due to it's larger volume.

- Increasing the ratio of water in the HLT to the water in

the mashtun will reduce the thermal lag due to the combination

of the two above points. e.g., with 1000L in the HLT, and 1L

in the mashtun, there will be almost no lag between the

vessels (excluding the usual losses).

- Increasing the efficiency of the heat exchanger will lead

to lower lag times (e.g., longer coil, better conductivity,

higher flow rate)

- Reducing thermal losses in the mashtun circuit can reduce lag time

(e.g., insulating), and reducing thermal losses in the HLT

will lead to quicker ramps.

It's quite likely that people who are not experiencing as much lag

time between HLT and mashtun as me are also brewing smaller batches,

and/or possibly with more water in their HLT. I re-ran all of my

temperature ramps using a smaller 20kg mashtun load, and the

results between the two algorithms were quite comparable:

The reason that there is not much difference is that the

overshoot algorithm exploits the fact that the HLT reaches it's

target well in advance of the mashtun due to the temperature

lag. If the lag is small, then the HLT still reaches it's

target well in advance, but the overall system temperature (T)

is much closer to the goal (G) due to the much higher weighting

of the HLT component of the system temperature (T). As a

result, the overshoot for the HLT is not allowed to be as large

as in the 40kg case.

You can see here that in this 20kg ramp from 50℃ to

65℃, that the HLT never gets hotter than 68℃ whereas

in the 40kg plot, the HLT temperature

goes as high as 69.2℃. Additionally, you can see that

the lag in the 20kg plot tops out around 5.5℃, whereas it is as

high as 8℃ in the 40kg plot. I

should also draw attention to the sawtooth pattern caused by the

0.3℃ system temperature deadband around G. This could

probably be reduced.

Other Considerations

Some other musings gathered during the investigation:

- The temperature of the HLT should not be allowed to

exceed 100℃ for obvious reasons.

- The delta between the mashtun temperature and the MLT

temperature should not be allowed to be high enough that

denaturing could become a serious concern. (Practically, it

is probably quite challenging to achieve denaturing unless the

flow rate is very slow).

- Knowing the thermal masses of the hot liquor and mash is necessary

in order to properly calculate T and G. Any brewer should

already have these figures handy.

- Knowing the thermal losses of the system, further

improvements could be made to keep the HLT temperature higher

for longer, rather than resorting to the inevitable duty

cycling towards the end of the ramp. This would require some

predictive modeling, but should not otherwise be

difficult.

- The system losses can easily be measured at any time by

knowing what the input power is (e.g., 5500W)

- Accurate ETAs could be computed.

- Rather than my crude deadband element control, I should look

towards more fine grained power control which controls duty

cycling based on a PID algorithm, but on the timescales we

operate at, the benefit may be trivial.

- The overshoot algorithm also does a better job at reacting

to transient events, such as topping up the HLT with cold

water, ramping temperature down, etc. This is because it is

always operating with knowledge of the full system

temperature.

- If pump controls are available to the control algorithm,

then the HLT could be further over-ramped, at the expense of

having to shut down the mash pump once the setpoint is

reached. This could also act as a failsafe against thermal

runaway due to an inadvertently shut-down HLT pump or a stuck

element relay, etc.

- If cold liquor is available, then the HLT could similarly

be further over-ramped, and then rapidly cooled back to the

goal condition. The HERMS coil connected to household water

at 10-15℃ can very rapidly cool the HLT.

Conclusions

In certain system configurations, it can be beneficial to

purposely over-ramp the HLT in a HERMS brewing setup to reach

different temperature steps if:

- The thermal lag between the HLT and mashtun is high

- The ratio of mass in the HLT to the mass in the mashtun is

low

There are possibly other situations which would warrant it, such

as low pump flow rate, or high system thermal losses, but these

should also manifest as high lag time.

I am considering leveraging the knowledge gained from this

experiment over to the STC1000+ project for use

in fermentation chamber temperature control.